No Motivation to Modify Product-Specific Method with Method Features for Different Products

July 14, 2023

On July 10, 2023, the Patent Trial and Appeal Board (PTAB) reversed an examiner’s finding of obvious on the basis of a failure to show a motivation to modify the prior art and a lack of a reasonable expectation of success. The appeal (No. 2023-002080, USSN 15/558,153, Technology Center 1700) of Ex parte MARK HETHERINGTON began with the filing of a Notice of Appeal on May 13, 2022, after filing the national stage application on September 13, 2017. The main appealed claim recited:

[a] process for producing a meal fraction of Brassica carinataoilseed having reduced sinigrin content, the method comprising:

a. pressing seeds of Brassica carinataoilseed to produce oilseed flakes;

b. cooking the oilseed flakes at a temperature in the range of 105°C to 180°C;

c. pressing the cooked oilseed flakes to remove oil from the oilseed flakes, thereby producing an oil fraction and a meal fraction;

d. treating the meal fraction with hexane to extract residual oil;

e. desolventizing-toasting the hexane-extracted meal fraction to remove residual hexane for a period of greater than 1 hour but less than 5 hours; and

f. drying the meal fraction to a moisture content of 12% or less, and

g. recovering a meal fraction of Brassica carinatahaving a sinigrin content of less than 20 μmol per gram of meal.

The claims were rejected by Examiner Stefanie Cox, supervised for the first three years of prosecution by Primary Examiner Michele Jacobson, under Supervisory Patent Examiner Amber Orlando, all of whom were conferees in the ultimate decision to force an appeal upon the applicant. That is, the applicant received nine office actions from Examiner Cox, of which five were signed by Examiner Jacobson, and the Examiner’s Answer (to send the appeal brief to the PTAB) was signed by Examiners Cox, Jacobson, and Orlando.

Given the breadth of the reversal of the examiner’s position, the prosecution history of the Hetherington application warrants discussion. The original independent claims of the Hetherington application, i.e., claims 1, 25, and 29, are provided below.

Claim 1: A process for removing at least one glucosinolate from a meal fraction of oilseed comprising:

(a) treating the meal fraction of oilseed with exogenous myrosinase to convert the at least one glucosinolate to a volatile isothiocyanate; and

(b) removing the volatile isothiocyanate from the treated meal fraction of oilseed under conditions of mild heat and negative pressure.

Claim 25: A process for removing at least one glucosinolate from a meal fraction of a Brassica carinataoilseed comprising:

(a) heating and applying pressure to the oilseed before, during, or after the extraction of oil;

(b) treating the meal fraction of oilseed with exogenous myrosinase to convert the at least one glucosinolate to a volatile isothiocyanate; and

(c) removing the volatile isothiocyanate from the treated meal fraction of oilseed under conditions of mild heat and negative pressure.

Claim 29: A process for removing at least one glucosinolate from a meal fraction of a Brassica carinataoilseed comprising heating and applying pressure to the oilseed before, during, or after the extraction of oil.

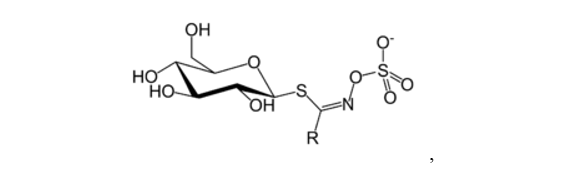

As detailed in the background of the Hetherington application and in the PTAB decision, the pressed fibrous remainder from Brassica carinata oilseed crops (also known as “Ethiopian mustard” or “carinata”) contains high levels of glucoinolates, i.e.,

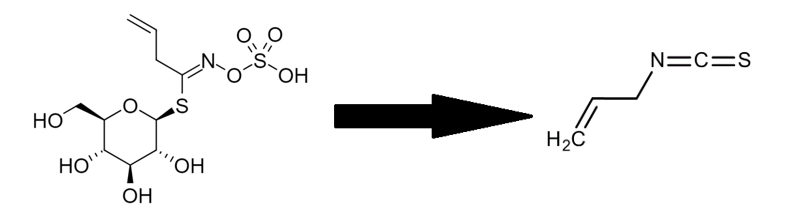

which limit its utility as a livestock feed. Carinata varieties are useful in making “biofuels,” and it would be useful to use the pressed fibrous remainder as feed, as is done for other oilseed plant materials. Glucosinolates and their metabolites can be harmful to livestock. Certain glucosinolates are known to be degraded by enzymes such as myrosinase, which is naturally present in mustard seeds, in a water hydrolysis breaking down, e.g., sinigrin (2-propenyl glucosinolate or allyl glucosinolate) into glucose, allyl isothiocyanate (responsible for the “bite” of horseradish and wasabi), and a sulfate anion, seen below.

Certain glucoinolates adversely affect animal health, and their hydrolysis can interfere with animal thyroid function.

The claims were initially rejected as lacking novelty over US 2005/0031768 A1 (Sakai), which describes obtaining or preparing a mustard seed stock, wherein

[t]he mustard seed stock is cracked, either by grinding or crushing or pressing or other activities. Alternatively, a mustard cake material produced by the prior crushing of mustard seed could also be used and that cake could be broken up or blended with any other raw mustard seed material to create the initial starting batch of mustard seed stock to be used in the process. Once the mustard seed stock has been cracked, the process can be continued.

[0027] Regardless of the starting material, the next stage in the process involves placing the cracked mustard seed stock along with water in a reaction chamber in which hydrolysis and distillation can occur under conditions of reduced pressure. Combining the cracked mustard seed stock with water to activate the enzyme myrosinase contained therein effectively creates an activated mustard slurry. The myrosinase hydrolysis will take place in a reaction chamber or the like in the activated mustard slurry and, on this basis, the hydrolysis will convert or degrade sinigrin in the activated mustard slurry into the fractioned allyl isothiocyanate. This is also known as allyl oil. The hydrolysis will be conducted over a period of time that is appropriate to create the requisite or desired amount of allyl oil, at a predetermined effective temperature and at a predetermined effective atmospheric pressure.

…

[0029] In terms of temperature of pressure, it is contemplated that the hydrolysis would likely take place in the range of 30 to 90 minutes in a preferable temperature range of 40° C. to 50° C. and at a pressure of 45 mM Hg. Under these conditions, hydrolysis of the sinigrin present in this type of mustard seed stock would produce volatile allyl oil, which is simultaneously distilled off of the reaction chamber and the activated mustard slurry. The removal of allyl oil from the activated mustard slurry by distillation will significantly improve the self-life of the prepared mustard products yielded from the remainder or spent mustard slurry, as the normal breakdown of allyl oil contributes significantly to product spoilage.

[0030] Thus, the process yields a spent mustard slurry in which hydrolysis has taken place and from which allyl oil is generated by myrosinase activity. The allyl oil is evaporated by conditions of increased temperature and decreased pressure and is distilled away from the remainder or remaining spent mustard slurry.

Thus, Sakai described a similar process with preference for a temperature range of 40 to 50°C and at a pressure of 45 mM Hg (underpressure).

The applicant amended the treating step to recite “adding treating the meal fraction of oilseed with exogenous myrosinase to the meal fraction of oilseed to convert the at least one glucosinolate to a volatile isothiocyanate” in the initial response, after which the main claims were rejected over Sakai and US 6,824,796 (Pusateri) on the basis that although Sakai failed to describe adding exogenous myrosinase to the meal fraction, Pusateri described adding exogenous myrosinase. After cancelling independent claims 1 and 29, the applicant amended claim 25 to further recite that “the temperature during heating is greater than 85°C but less than l80°C,” and “the pressure is applied using an expeller or screw press.” The applicant argued that Sakai teaches a temperature range of 40-50°C for myrosinase-catalyzed hydrolysis of sinigrin, which the applicant noted, pointing to Sakai’s ¶ [0004] was taught to preserve activity of the myrosinase enzyme (“any method of production that involves heating the mixture to temperatures above 45° C. will make impossible to maintain the activity of myrosinase”).

The claims were then rejected as obvious over a master’s thesis entitled “Analysis of Oilseed Glucosinolate and Their Fate During Pressing or Dehulling” by Deyun Yuan of the University of Saskatchewan (Yuan). The examiner argued that Yuan’s introduction on pp. 10 to 14, which include the text provided immediately below on Yuan’s p. 14.

Many published methods described extraction at temperatures between 70 and 100°C in order to inactivate the endogenous myrosinase (Cools and Terry, 2012; ISO, 1992; Kiddle et al., 2001; Szmigielska and Schoenau, 2000; Wathelet et al., 1999). Nevertheless heat treatment is controversial. Tsao et al. (2002) pointed out that heating before extraction may not inactivate myrosinase completely, especially when the moisture content is less than 8%. In other cases, heating may lead to degradation of glycosides like glucosinolates.

In response, the applicant cancelled all pending claims and introduced a new independent claim as indicated below.

Claim 38: A process for producing a meal fraction of Brassica carinataoilseed having reduced sinigrin content, the method comprising:

a. pressing seeds of Brassica carinataoilseed to produce oilseed flakes;

b. cooking the oilseed flakes at a temperature in the range of 105°C to 180°C;

c. pressing the cooked oilseed flakes to remove oil from the oilseed flakes, thereby producing an oil fraction and a meal fraction;

d. treating the meal fraction with hexane to extract residual oil;

e. desolventizing-toasting the hexane-extracted meal fraction to remove residual hexane; and

f. drying the meal fraction to a moisture content of 12% or less, and

g. recovering a meal fraction of Brassica carinatahaving a sinigrin content of less than 20 μmol per gram of meal.

The applicant argued that Examples 9 to 12 of the application show that its presently claimed process results in substantial decreases in sinigrin content in the meal fraction of B. carinata oilseed. Referencing the experimental evidence in the application, the applicant indicated that Sample 1 is a control sample comprising defatted B. carinata variety A110 meal produced by grinding B. carinata oilseed in a blender to form a uniform meal, without the application of pressure, heating the meal at 80°C for 20 minutes, allowing the meal to cool, then extracting the meal with hexane four times to produce a defatted meal sample to obtain a defatted meal sample with a sinigrin concentration of 68.72 μmol/g. In contrast, the applicant pointed to its Samples 2 and 3 with the same variety oil seed, this time prepared with pressure applied by an expeller or extruder, and heating at a temperature greater than 105°C, leading to respective sinigrin contents in defatted meal samples of 13.13 μmol/g (reduced 81% from control) or 18.75 μmol/g (reduced 73% from control). The applicant pointed out that Yuan disclosed nothing about pressure or the tolerability of processing to heating above the boiling point of hexane, and illustrated that Yuan’s process leads to sinigrin contents in defatted meal samples of 117.55 μmol/g.

The examiner responded by rejecting the claims over Verkoeijen (US 2013/0101723 A1) and Yuan, arguing that Verkoeijen describes heating oilseed flakes after grinding to 120 to 160°C, which could be Brassica carinata oilseed. In fact, Verkoeijen described “a process for obtaining a polyunsaturated fatty acid having at least 20 carbon atoms (LC-PUFA) or an oil comprising a LC-PUFA from seeds,” according to Verkoeijen’s ¶¶ [0001] and [0005], and although only relating to the oil and not the press cake / pressed fibrous mass, Verkoeijen’s ¶ [0028] described a preference for seeds of a (transgenic) plant of the family Brassicaceae, including Brassica carinata. The examiner considered Verkoeijen to basically disclose all claimed elements, but relied on Yuan to remedy Verkoeijen’s failure to specifically disclose desolventizing-toasting to evaporate hexane from the meal fraction.

Although Verkoeijen was admitted not to disclose using the press cake or the sinigrin content feature, the examiner cited form language from the MPEP that “[w]here the claimed and prior art products are identical or substantially identical in structure or composition, or are produced by identical or substantially identical processes, a prima facie case of either anticipation or obviousness has been established,” citing to In re Best, 562 F.2d 1252, 1255 (CCPA 1977). Although such inherency rejections, discussed in MPEP § 2112, traditionally applied to situations involving otherwise anticipatory rejections, but for the missing inherent element / property, the rejection here (approved by a supervisory examiner) reassembled unconnected portions of Verkoeijen’s disclosure, then concluded that the reconstruction of the claims inherently possessed missing features as a consequence of tracing the claims. Many prosecutors may be familiar with this type of improper inherency rejection, as it appears to be in accord with present USPTO examining corps policy.

The applicant responded with 12 pages of detailed remarks on the deficiencies of Verkoeijen and Yuan, as well as evidence of knowledge in the art prior to filing, citing Molecules 2015, 20, 15827-15841 (Bhandari[1]), entitled “Comparison of Glucosinolate Profiles in Different Tissues of Nine Brassica Crops,” and Phytochem. 1991, 30(8), 2623-2638 (Daxenbichler[2]), entitled “Glucosinolate composition of seeds from 297 species of wild plants.”

The examiner responded by rejecting the claims again, supplementing Verkoeijen and Yuan with US 2010/0234569 A1 (Helling), supplementing the otherwise identical rejection with the assertion that Helling[3] describes that press cakes or meal fractions resulting from conventional seed oil extraction processes are recovered after the oil extraction step to use as a feed composition for a variety of classes of animals, citing to Helling’s FIG. 1 and ¶¶ [0003] and [0023]. The examiner concluded that it would have been obvious to recover the press cake of Verkoeijen because Helling discloses that the press cake is useful as a novel feed composition for animals.

The applicant responded twice more, in the penultimate response submitting a 12-page declaration from an expert with over 35 years in the oilseed processing industry, detailing the results achieved by the claimed inventions and the deficiencies of the cited art, and amending step (e) to recite “desolventizing-toasting the hexane-extracted meal fraction to remove residual hexane for a period of greater than 1 hour but less than 5 hours.” The examiner maintained her position on the inherency of recovering a meal fraction having the claimed sinigrin content, dismissing the prior art’s failure to recognize the problem of high sinigrin content based on the commonly-cited non-precedential opinion[4] of the former Board of Patent Appeals and Interferences, Ex parte Obiaya, 227 USPQ 58, 60 (Bd. Pat. App. & Inter. 1985), found in MPEP § 2145(II) under “Arguing Additional Advantages or Latent Properties.” Unlike the claimed invention and most claims against which it is cited, In re Obiaya opines on an apparatus claim[5] which was argued to provide shorter response times based upon the use of a well-known component, but the well-known component (labyrinth heater) was motivated to be used for maintaining uniform temperatures. In a method claim reciting the shortening of the response time, it is likely that the opinion in Obiaya would have been different.

The PTAB made relatively short shrift of the positions taken by the examining corps, without addressing the secondary evidence to which the appealed claims were at least partially tailored. The PTAB noted that Helling pertains to canola or rapeseed press cake, not to carinata, that Yuan is the only reference discussing the potential use of carinata press cake, but states that carinata seed meal has the highest sinigrin content of any of the carinata-derived materials tested in Yuan, and observes on p. 64 that this “might suggest that this material may not be the best candidate as feed for farm animals.” On this basis, the PTAB concluded that no motivation to combine Verkoeijen, Yuan, and Helling to arrive at the claimed invention was supported by the evidence of record.

In addition to this, citing to Yuan’s disclosure that, at the time of the invention, it was known that carinata press cake had little utility as an animal feed component because of its high sinigrin content, the PTAB found that the examiner failed to cite any prior art description that there would have been a reasonable belief that the meal fraction produced by Verkoeijen’s process, as modified in view of Yuan and Helling, would have a reduced sinigrin content. On this second basis, the PTAB opined that the examiner had not established a prima facie case of obviousness.

The result in the Hetherington application leaves questions about which scope of the claims could have been obtained earlier in prosecution. For example, it is not clear that the use of pressure and high temperature was obvious as submitted in the first claim amendment. Notwithstanding, the Hetherington application is a reminder to applicants that there is a strong case of non-obviousness when the reference relied upon by the examiner itself indicates that the claims are non-obvious, as was the case in both Sakai and Yuan. In addition, although the USPTO examining corps applies increasingly outlandish inherency-obviousness rejections, based on Frankensteinesque reconstructions of active claims.

Unlike the approach taken the Hetherington application, the Federal Circuit has held that “[a] party must … meet a high standard in order to rely on inherency to establish the existence of a claim limitation in the prior art in an obviousness analysis—the limitation at issue necessarily must be present, or the natural result of the combination of elements explicitly disclosed by the prior art.” Par Pharmaceutical v. TWi Pharmaceuticals, Inc., 773 F.3d 1186, 1195-1196 (Fed. Cir. 2014). The Federal Circuit has also stated that

[w]e have previously stated that the use of inherency in the context of obviousness must be carefully circumscribed because “[t]hat which may be inherent is not necessarily known” and that which is unknown cannot be obvious.” Honeywell Int'l v. Mexichem Amanco Holding, 865 F.3d 1348 1354 (Fed. Cir. 2017) citing In re Rijckaert, 9 F.3d 1531, 1534 (Fed. Cir. 1993) (quoting In re Spormann, 363 F.2d 444, 448 (1966)); see also PAR Pharm., Inc. v. TWI Pharm., Inc., 773 F.3d 1186, 1195 (Fed. Cir. 2014). … What is important regarding properties that may be inherent, but unknown, is whether they are unexpected. All properties of a composition are inherent in that composition, but unexpected properties may cause what may appear to be an obvious composition to be nonobvious.

Honeywell Int'l v. Mexichem Amanco Holding, 865 F.3d 1348, 1354-1355 (Fed. Cir. 2017) citing In re Papesch, 315 F.2d 381, 391 (CCPA 1963). In more patent-friendly eras of the USPTO, inherency is traditionally applied in situations in which “the allegedly inherent characteristic necessarily flows from the teachings of the applied prior art,” as indicated in MPEP § 2112(IV), and was often confined to situations in which a single referenced disclosed all elements of the claim except for the missing property or characteristic, at least in unpredictable arts. However, the PTAB (like the Federal Circuit) is not constrained to trends in applying inherency by the USPTO examining corps, bound to follow MPEP guidance. Accordingly, to gain a different analysis of the claims, it may be necessary at the USPTO to take your arguments beyond even pre-appeal conferences, to the PTAB.

Beyond this, as a procedural consideration, many examiners in training are coached into rejecting claims by their signatories, i.e., primary examiners (in this case Examiner Jacobson), rather than considering the patentability of claims. In general, the USPTO work count system makes examiners more fearful of being reversed by quality control (often including the same SPEs who sign Examiner’s Answers) than by the PTAB, since a reversal by QC can obligate examiners to do work without accreditation of the work, while a reversal by the PTAB can assure examiners of safe allowance of claims without fear of QC reversal.

[1] Bhandari was alleged to describe “that cauliflower seeds contain 49.52 μmol/g glucosinolate of hich 34.09 μmol/g is sinigrin while seeds of Pakchoi contain 107.75 μmol/g glucosinolate of which only 0.07 μmol/g is sinigrin.”

[2] Daxenbichler was alleged to list “the glucosinolate content and composition for seeds of almost 300 of brassicaceae and allied species. As shown in Table 2 [of Daxenbichler], total glucosinolate content varies widely.”

[3] The examiner’s supplement to the rejection was merely general knowledge on common seed oil extraction, applicable to different plant types and already explained in substantial detail to be inapplicable to the particular variety claimed, Brassica carinata.

[4] The Obiaya form language in the MPEP, also cited by the examiner here, was “[t]he fact that applicant has recognized another advantage which would flow naturally from following the suggestion of the prior art cannot be the basis for patentability when the differences would otherwise be obvious.” For precedential opinions, please see https://www.uspto.gov/patents/ptab/decisions-and-opinions/precedential.

[5] 1. A combustible fluid and oxygen concentration sensor comprising: a. a combustible concentration analyzer; b. an oxygen concentration analyzer; c. conduit means for routing a fluid sample past said combustible concentration analyzer and oxygen concentration analyzer; d. an inlet port to said conduit means for receiving a sample fluid; e. an outlet port from said conduit means for ejecting said sample after analysis; f. means for producing fluid flow in said conduit means from said inlet port to said outlet port; g. means to connect the combustible concentration analyzer to an indicator; and h. means to connect the oxygen analyzer to a second indicator; i. said conduit means comprising: i. first and second portions arranged to divide the flow into separate paths downstream from said inlet and upstream from said flow producing means; ii. said first portion supplying the oxygen analyzer but not the combustible analyzer [sic, analyzer] with sample fluid; iii. said second portion supplying the combustible analyzer but not the oxygen analyzer with sample fluid; iv. a heater associated with said second portion upstream of said combustible analyzer; and v. an inlet for providing air to said second portion upstream of said heater, to insure complete combustible analysis within said combustible analyzer.